Table Of Content

Thus, helping businesses save money while improving safety and efficiency on the production floor. These belts use interlocking slats to carry items from one end of the belt to another. They are ideal for moving heavy objects over long distances and can handle high-volume production lines.

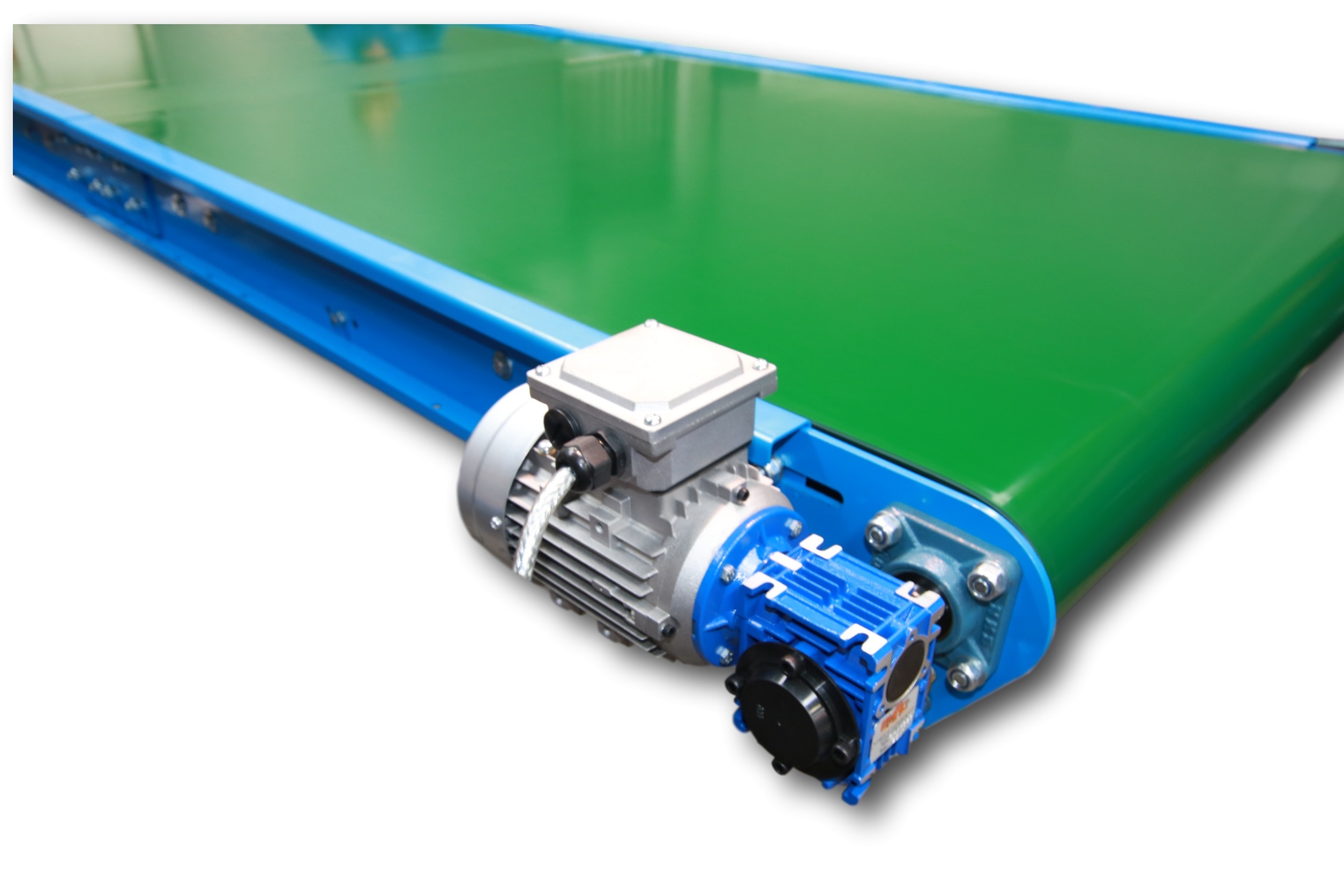

Parts of the Conveyor Belt System

These units use an electric track inclined to pull the chairs up or down the mountainside. We also need to consider hygiene requirements – for example how much cleaning is required and the type. This is important as it helps us design the conveyor – for example including catch trays, drop-down sides or easily removable belts. Space is one of the first things our engineers consider when approaching a new conveyor system project. Space is at a premium for most manufacturing facilities and understanding the existing factory layout and relationships between different equipment is essential for designing an effective system.

Pallet Handling Conveyors

Let’s take a look at how conveyor belts work and why they’ve stood the test of time. The choice of conveyor belt has a significant impact on the system’s performance, maintenance requirements, and overall cost-effectiveness. One of the most crucial components of a conveyor system is the belt tension adjustment mechanism.

The Demand for Smart and Efficient Conveying Systems - Food Engineering Magazine

The Demand for Smart and Efficient Conveying Systems.

Posted: Wed, 25 Jan 2023 08:00:00 GMT [source]

Supply Chain Solutions

A conveyor belt system is a mechanical device that transports materials or products from one location to another within a facility or across distances. It consists of a continuous belt made from various materials, including rubber, fabric, or metal, which is stretched over a series of pulleys. They are an integral part of modern industrial operations, logistics, and supply chains. Conveyor belt systems are integral components of numerous industrial processes, providing a reliable and efficient means of transporting goods and materials across various stages of production and distribution.

Lack of adequate access for operation and maintenance is a critical productivity and safety issue. Even in greenfield projects, conveyors are often placed in tunnels or galleries with access only to one side to keep capital costs low. This basic design mistake makes it less likely that a squeaky bearing on the inaccessible side will be replaced before it fails. The CEMA design manual suggests minimum clearances around the different sections of the conveyor.

This includes not only the initial cost of purchasing and installing the system but also the ongoing expenses of maintaining and repairing it. By factoring in these costs during the design process, it is possible to create a system that is both efficient and cost-effective in the long run. Whether you’re stuck in the planning phases of getting a newplant up and running or your current conveyor system configuration isunderperforming, we will find the solutions to your problems.

Visit Designed Conveyor Systems to learn more about conveyor design services in Franklin, TN today!

Central to the concept of modern manufacturing, warehousing, and logistics, these systems streamline operations, ensuring that materials move smoothly from one point to another with minimal human intervention. The design of a conveyor belt system is crucial, as it directly impacts the system’s efficiency, safety, and operational cost. A well-thought-out conveyor belt system design accommodates specific industry needs, handling requirements, and spatial constraints, thereby enhancing the overall productivity and safety of the workplace. By automating the movement of materials, these systems reduce the likelihood of errors and accidents, making them indispensable in today’s fast-paced industrial environments. When designing conveyor systems, it is crucial to consider various factors to ensure its efficient operation. These factors include product characteristics, material handling requirements, environmental conditions, type of conveyor, layout, safety, maintenance requirements, and cost.

Machine learning algorithms can identify patterns, predict maintenance needs, and dynamically adjust the conveyor system to maximize production output. These technologies enable manufacturers to achieve higher levels of efficiency, reliability, and cost-effectiveness. Advancements in material science have led to the development of lightweight yet high-strength materials for conveyor belts. These materials offer enhanced durability, reduced energy consumption, and increased load-carrying capacity. Lightweight conveyor belts minimize strain on the system, improve energy efficiency, and enable higher production output. By leveraging automation in conveyor belt design, manufacturers can achieve higher levels of productivity, efficiency, and safety in their operations.

Your conveyor system should be able to handle your facility’s average transfer rate as well as periods of peak demand due to seasonal fluctuations. The number of products you need to transport per hour (or per minute) will determine conveyor length and speed. Installing the wrong conveyor system will quickly undermine a warehouse’s operational efficiency, leading to higher cost and lower customer satisfaction, eventually stripping the business of its competitive advantage. Also, there are several factors to consider when trying to identify and purchase the ideal conveyor system for your warehousing or distribution facility.

After all, conveyors are proving theirvalue in labor and maintenance cost savings for more operations now. Do your materials need a specific environment in order to remain in proper condition? Food distribution centers will often use conveyor systems and might need the facility to remain clean and within a certain temperature range. Other materials might require a certain amount of humidity or a particular temperature. Your conveyor design will need to be able to operate efficiently in these specific conditions.

And it’s their adaptability that gives them the ability to serve such a wide range of industries. This type of conveyor is perfect when an item needs to arrive at the end of the line in a specific orientation. As its name implies, this machine lifts and rotates products, then sets them back on the line. A gravity conveyor uses the earth’s gravity and the load’s weight to move products. They are generally used for loading and unloading of trucks, and for transportation through picking areas.

No matter how you choose to design your conveyor, keeping the above tips and principles in mind can help ensure you have the most efficient system for your product or material. A conveyor system can be used to move materials from point ‘A’ to point ‘B’, but did you know it can also be used for sorting, cooling, and screening materials? Perfect for recycling, bulk processing, and metal casting, a quality conveyor can move your business along the right path. Zuken offers innovative tools like its E3.series software to enable the development of modern conveyor system design. IoT enables real-time monitoring and control through a proliferation of sensors, wireless connectivity, and the use of a centralized control dashboard.

No comments:

Post a Comment